8 Rivers recently announced a breakthrough that will transform ultra-low-carbon hydrogen production and the production of hydrogen derivatives such as ammonia, methanol, and sustainable aviation fuels (SAF).

This second generation of our 8RH2 solution uses a proprietary CO2 Convective Reformer (CCR), an innovation that enables both record-low emissions and unparalleled cost-effectiveness.

We recently sat down with our team to discuss what makes 8RH2 unique, how the CCR works, and how producing ultra-low-carbon products like hydrogen and ammonia will be essential to global decarbonization.

What makes 8RH2 so unique?

8RH2 stands out for its low emissions and its high cost-effectiveness.

Where competitor technologies struggle to reach >95% carbon capture, 8RH2 easily exceeds 99% – well above the Rocky Mountain Institute’s 95% threshold for when carbon-capture-based clean hydrogen technologies make climate sense.

We’re also proud to say we lead the pack on affordability. With operating costs approximately 5-10% less than competing technologies, we combine the ultra-low-carbon production that our climate needs with the ultra-affordable price tag that the industry needs to scale.

Our technology achieves this level of performance by leveraging existing equipment and infrastructure in a novel process that captures pipeline-quality CO2 inherently, without backend carbon capture and purification. This combination accelerates deployment time.

Both the ultra-low emissions and the ultra-high cost-effectiveness stem from 8RH2’s standout innovation, the CO2 Convective Reformer.

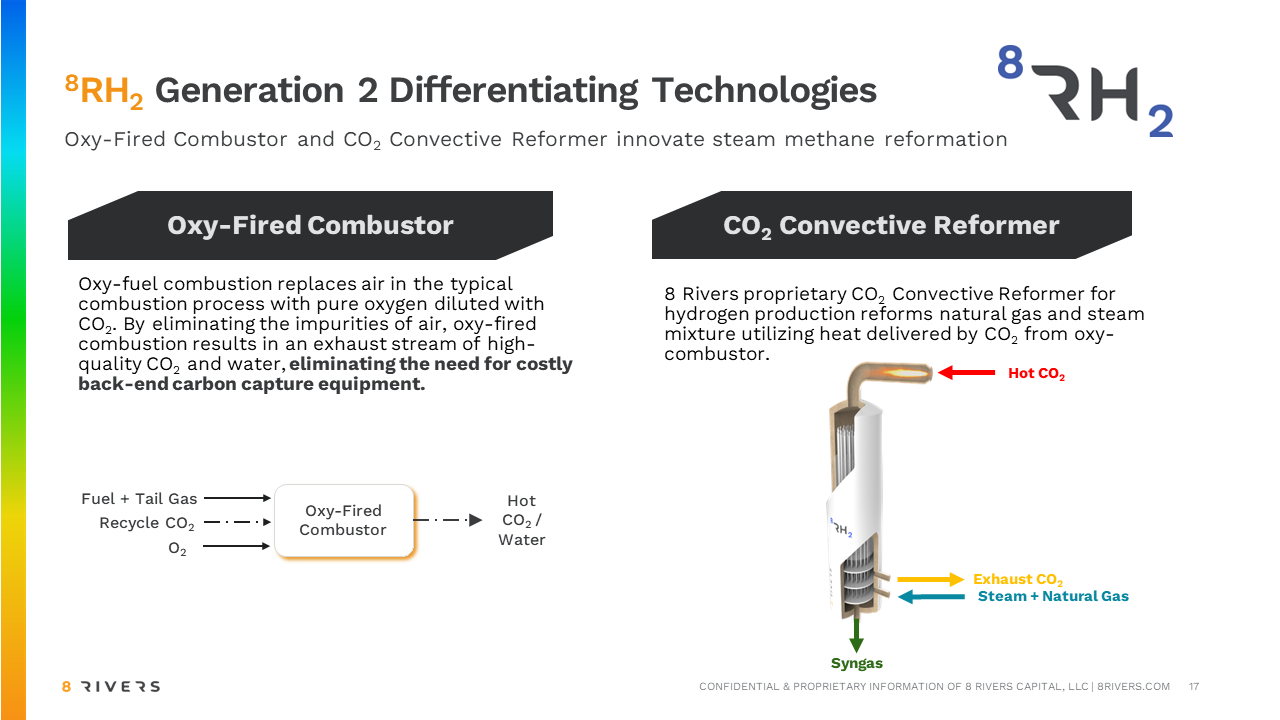

Figure 1: In 8RH2 hydrogen production, oxy-combustion enables standout efficiency.

What does the CO2 Convective Reformer do, and why is it important?

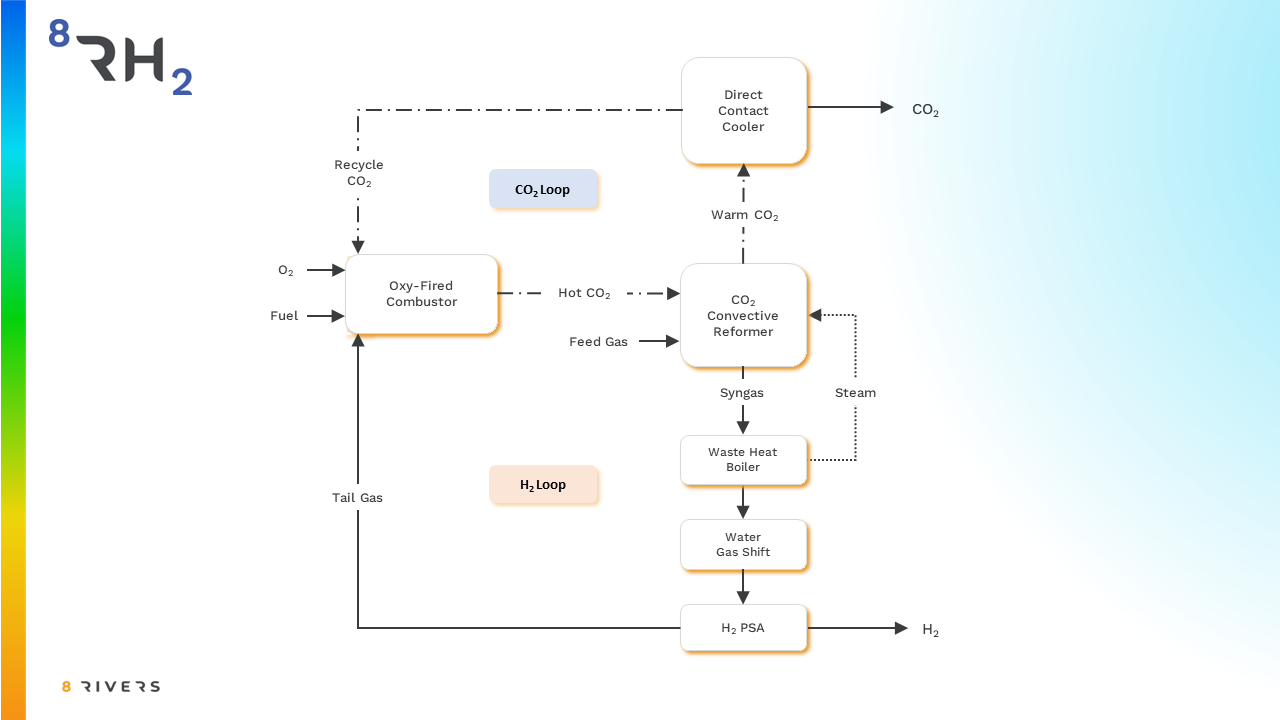

The CO2 Convective Reformer (CCR) uses CO2 as a heating medium. This novel advantage improves the carbon capture rate within 8RH2, bringing both emissions reductions and efficiency gains to our hydrogen production.

The CCR has two separate gas streams and a catalyst. In the first stream, which enters from the top, we have CO2, heated by oxy-combustion. In the second stream, which enters from the side, we have natural gas (the reaction’s feedstock) and steam.

Thanks to the CCR’s tube-in-tube construction, the two gas streams can interact without ever mixing. Natural gas and steam react in the presence of the catalyst and the heat provided by the hot CO2, then exits the CCR through the bottom as syngas.

The hot CO2 produced via oxy-combustion goes out of the side as exhaust, having never directly mixed with the syngas. This gas separation enables the inherent carbon capture that makes 8RH2 so game-changing.

By eliminating the need for back-end carbon capture, 8RH2 saves both equipment costs and carbon emissions, enabling the 5-10% operational savings and >99% carbon capture that stands head and shoulders above its competitors.

What makes 8RH2 so ultra-low-carbon?

8RH2 combines the best of two legacy hydrogen technologies in a way that enables significantly more carbon capture.

The first, steam methane reforming (SMR), separates the gasses. But, because SMR systems are either air-fired or not pressurized, the ambient air contaminates the flue gas CO2 despite the separation.

The second system, autothermal reforming (ATR), does the reverse: it employs pressurization but uses only one flue stream, meaning the gasses aren’t separate.

In both cases, the crossed flue gas streams require back-end carbon capture and purification equipment to separate the CO2 from contaminants.

Because no process is completely efficient, this back-end separation means that CO2 inevitably escapes to the atmosphere when nitrogen and other contaminants are removed. Plus, post-combustion carbon capture is an energy hog, reducing overall efficiency.

Consequently, both of these methods struggle to break the 95% carbon capture that think tanks such as RMI say is the threshold for hydrogen + capture solutions to make sense as new-build energy transition investments. 8RH2, on the other hand, exceeds 99.9% carbon capture inherently, without extra cost.

Figure 2: 8RH2 – Illustrative System Diagram

What makes 8RH2 an especially economical option?

8RH2 has zero direct CO2 emissions and can significantly surpasses electrolytically-generated hydrogen on affordability. We use natural gas, a less expensive input than electricity.

Meanwhile, compared to competitors that also pair natural gas with carbon capture, we achieve both lower carbon intensity AND significantly lower costs. After all, back-end CO2 capture is expensive.

So the CCR’s ability to capture CO2 inherently is huge for cost savings and emissions reductions. Our greater efficiency saves 5-10% in operational costs compared to SMR and ATR technologies.

To make the impact we need, clean energy technologies must scale quickly and globally. But companies will only adopt these technologies if they make economic sense.

To meet that threshold, solutions must demonstrate lifetime costs lower than the unabated fossil fuel options and capital costs low enough to compete too.

8RH2 meets both of those parameters. That’s a huge achievement, both for our engineers and for the climate.

How can ultra-low-carbon hydrogen and ammonia advance the energy transition?

According to McKinsey and Company, ultra-low-carbon hydrogen and ammonia could eliminate 80 Gigatons of otherwise hard-to-abate emissions by 2050. Its potential is threefold: first, by decarbonizing just the hydrogen and ammonia we already use for oil & gas refining, fertilizer production, and defense, we can reduce global greenhouse gas emissions by ~4%.

Second, we can use hydrogen to decarbonize sectors (such as high-horsepower transportation and heavy industry) that can’t be electrified directly.

By co-locating hydrogen production facilities with those offtakers in a “hydrogen hub” approach, we can minimize the expense, resources, and risk involved with storage and transportation, further boosting its positive impact.

Third, we can use clean hydrogen and ammonia to overcome geographic clean energy barriers. Take Japan: its island isolation, mountainous terrain, and steep coastal shelf inhibits its ability to scale renewable energy generation or battery storage.

Thanks to ammonia’s ability to transport hydrogen, Japan and countries with similar conditions, such as South Korea, can import the clean fuels they then use to decarbonize their industrial economies.

How soon can 8RH2 deploy to energy-transition projects?

Climate experts know that to meet our mid-century goals, we need to rapidly scale our decarbonization solutions.

Thankfully, 8RH2 is available for immediate deployment. Its easily deployable technology, scalable design, and affordable price point hits the metrics that industries need to launch their decarbonization strategies now.

The world needs solutions that enable an energy future that is abundant as well as clean. 8RH2 provides the ultra-low-carbon, cost-effective hydrogen, ammonia, and hydrogen-derivatives that are needed to make that future happen.

—

If you’d like to learn more about the 8RH2 technology, its applications, and its potential to accelerate your organization’s specific decarbonization plans, please contact us – we’d love to connect.