This January, 8 Rivers began 2024 with a bang by announcing Cormorant Clean Energy, an ultra-low-carbon ammonia production facility in Port Arthur, Texas. This commercial debut of 8RH2, 8 Rivers’ ultra-low-carbon hydrogen production technology, will produce clean ammonia for use in sectors that need clean-burning fuels.

As ammonia releases no carbon dioxide when burned, it will play an important role in decarbonizing hard-to-abate industries, including long-haul transportation, industrial processes, power generation, and more. By producing ammonia through an ultra-low-emissions production process, Cormorant Clean Energy will provide truly clean ammonia with best-in-class efficiency and carbon capture.

8RH2’s Big Debut

This first commercial-scale 8RH2 deployment marks the culmination of years of tireless work. In May 2023, 8 Rivers announced 8RH2’s CO2 Convective Reformer (CCR), a technology with roots deep in 8 Rivers’ innovation history around how to remove CO2 emissions from industrial processes.

Chief Inventor Rodney Allam pioneered the use of oxy-combustion combined with a power cycle with inherent carbon capture to eliminate CO2 emissions while drastically reducing cost. First applied in the Allam-Fetvedt cycle, the first new power cycle invented since World War II, innovation around utilizing CO2 as a working medium provided the inspiration for developing 8RH2 which provides a game-changing combination of affordability, scalability, and sustainability. Thanks to the CCR technology and inherent carbon capture by design, 8RH2 attains greater than 99.9% carbon capture. (Listen to Nobel prize-winning Rodney Allam, MBE explain the 8RH2 breakthrough here!)

To launch 8RH2 from ideation to commercialization, we needed a trusted partner to provide, maintain, and guarantee the equipment needed to build our ultra-low-carbon hydrogen and ammonia projects. We also needed to establish a secure supply and reliable delivery pipeline both for Cormorant and our anticipated future projects.

That’s why, in January, we also announced a strategic partnership with Casale SA to make them the exclusive global supplier of 8RH2’s CCR technology. For Cormorant and beyond, Casale will provide the CCR technology needed to deploy the 8RH2 technology. At Cormorant, we will also deploy Casale’s ammonia synthesis loop technology to convert 8RH2’s ultra-low-carbon hydrogen into clean ammonia.

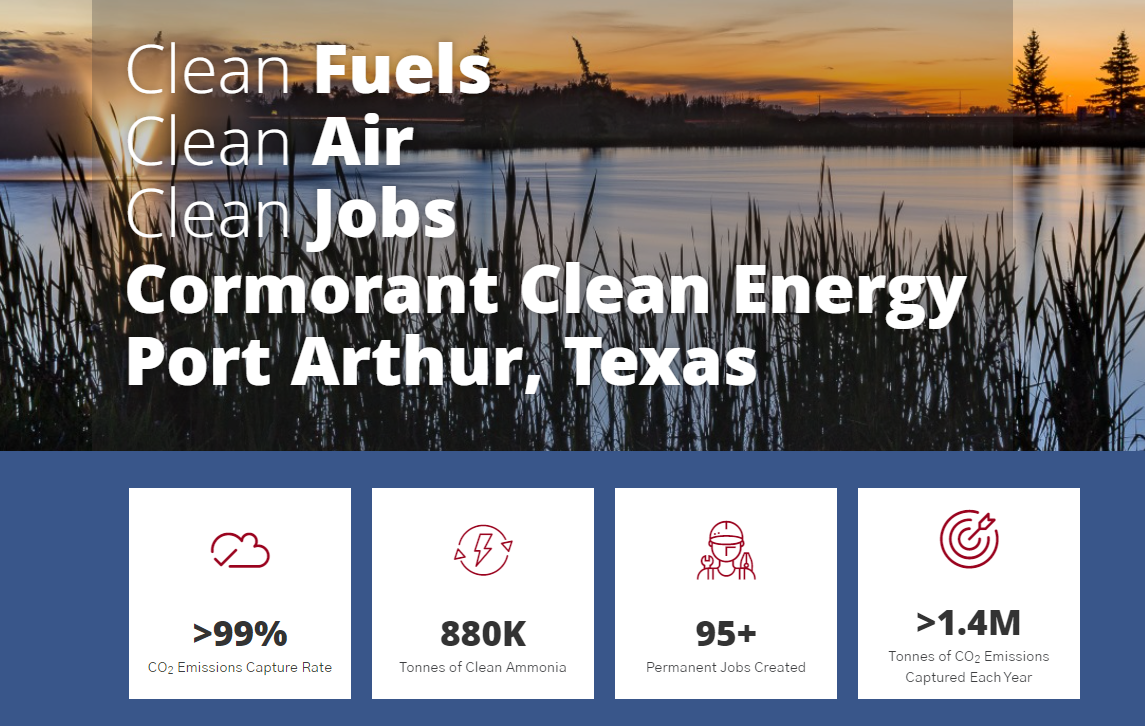

Clean Fuels, Clean Air, Clean Jobs

Cormorant Clean Energy stands out amongst Port Arthur, Texas projects for its contribution to the health of the community and the broader world.

In terms of clean fuels, Cormorant will produce an estimated 880,000 tons of ammonia annually while capturing more than 1.4 million tons of CO2 – a >99% CO2 capture rate. That high level of carbon capture at lower costs is essential to providing ammonia that is both truly clean and affordable, the combination that hard-to-abate industries will require to deploy clean fuels for their decarbonization needs. (Check out our 2023 Net Zero Solutions report for more detail on how scaling ultra-low-carbon, cost-competitive clean fuels is a key pillar of 8 Rivers’ technology portfolio.)

Thanks to its extremely high CO2 emissions capture rate, Cormorant will produce valuable clean ammonia without introducing new emissions or harmful pollutants into the air in Port Arthur and surrounding communities.

And of course, Cormorant’s strategic location in the U.S. Gulf Coast will bring clean energy jobs to the region while benefiting from its existing infrastructure, skilled workforce, and commitment to the energy transition. We anticipate the site will bring over $1 billion in investment to the Gulf Coast while creating more than 1,000 new construction jobs from 2024 to 2027.

Consistent, transparent community engagement around impact and development is essential to clean energy projects. The 8 Rivers team values community partnerships and has been working with local and regional leaders, community members, and prospective partners at all stages of Cormorant’s planning. We’re committed to continuing to build these relationships as the project gets underway.

What’s Next

When will Cormorant Clean Energy be up and running, and where will its clean ammonia go?

In terms of timeline, we’re set to break ground on Cormorant Clean Energy in 2025 and anticipate it will be operational in 2027.

In terms of destination, the ultra-low-carbon ammonia produced at Cormorant will be exported to Asia, where a robust decarbonization strategy is driving demand for clean fuels to reduce power plant emissions by co-firing ammonia in existing power plants.

We’re confident this milestone 8RH2 deployment will be the first of many. The technology primarily leverages existing infrastructure and equipment, rather than introducing novel or unproven technologies. That pragmatism makes it an ideal solution for rapid deployment in industrial decarbonization applications.

As we embark on the Cormorant Clean Energy project, we’re keeping our eyes on mid-century net-zero emissions goals. By demonstrating 8RH2’s advantages in a commercial setting, we’re excited to establish a replicable roadmap that can help ultra-low-carbon fuels advance decarbonization on a global scale.